Features

Heat resistance

Maximum heat resistance: 600 ± 50°C, 800 ± 100°C, 1000 ± 200°C

Chemical resistance

| Properties | SL-600 | SL-800 | SL-1000 | |

| Acid | H2SO4 (5%, 20°C) | No effect after 100 hours | ||

| H2SO4 (98%, 70°C) | No effect after 5 hours |

No effect after 1 hours |

No effect after 20 hours |

|

| HCl (5%, 20°C) | No effect after 10 days | |||

| HNO3 (5%, 60°C) | No effect after 100 days | |||

| Alkali | NaOH (20%, 20°C) | No effect after 200 days | ||

| Solvent | — | No effect | ||

Weather resistance

1) No effect on ceramic layer after 30 cycles salt spray test of under the below condition.

| Condition | Temperature | Humidity | Time |

| 5% salt water spray | 35±1°C | Over 95% | 2 hours |

| Dry hot air | 60±2°C | — | 4 hours |

| Wetting | 50±2°C | Over 95% | 2 hours |

2) No effect after 4000 hours of weather meter test. (Equivalent to 15 years of outdoor use)

Shock resistance

The barcode label withstands a shock caused by a 200g steel ball dropped from a height of 50cm with no damage.

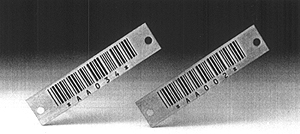

Super mini label The minimum short side length of a label can be 2 mm.

Specifications

| Material | Heat resistance stainless steel substrate and ceramic layer |

| Thickness | 0.2, 0.4, 0.7, 1.0 mm |

| Mounting | Screw Spot welding Double-sided adhesive tape Soldering Pocket method |

| Barcode | All kind of barcodes including 2D codes |

| PCS | More than 75% |